Deburring is the most important phase as it prepares the product for subsequent processing (grinding, polishing, vibratory finishing or tumbling, etc.).

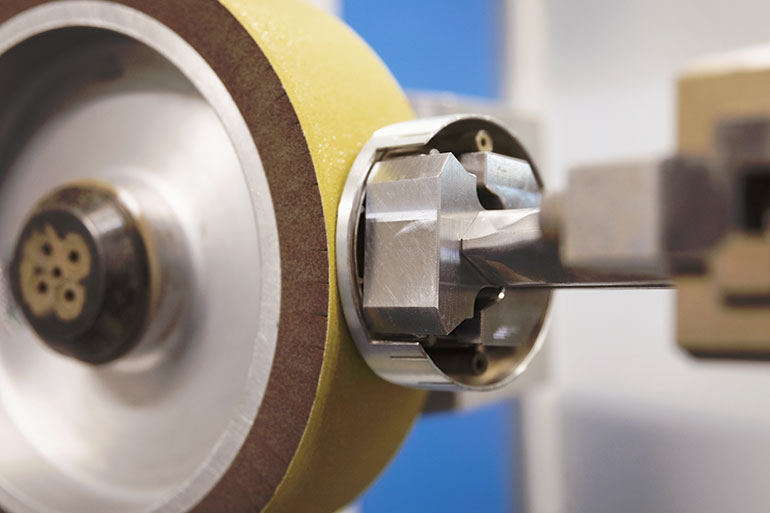

This finish is obtained thanks to abrasive belts, abrasive wheels, cutters, etc., which smooth the imperfections of the piece caused by previous processes such as cutting, moulding or cutting.

Deburring requires extreme attention, especially on medium-large lots, since even the smallest mistake could deprive the product of its natural shape.

For this reason, you need to rely on competent and equipped companies: S&G offers high quality standards, thanks to the know-how and a constantly updated machinery department.

Strengthened by the experience gained year after year, we work different materials: without any problem we perform brass deburring, aluminium deburring, zamak deburring, stainless steel deburring and copper deburring.

Specialised department for die-casting and foundries

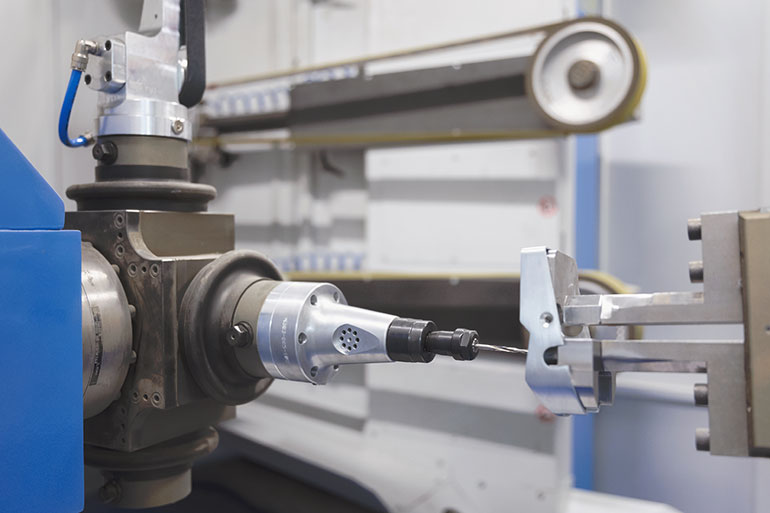

S&G has recently added a separate department that offers specialised high-quality processes for die-casting and foundries

Deburring of small, medium and large pieces thanks to the dedicated machine department with automated island capable of deburring, milling, sanding and drilling small holes all in one cycle. We are able to give the customer superior quality and competitive prices on the market, never forgetting to keep the requested timelines.

For more particular processes we do not exclude manual processes with orbital and cutters.

IT

IT